Abstract

We propose a novel technique for the automatic design of molds to cast highly complex shapes. The technique generates composite, two-piece molds. Each mold piece is made up of a hard plastic shell and a flexible silicone part. Thanks to the thin, soft, and smartly shaped silicone part, which is kept in place by a hard plastic shell, we can cast objects of unprecedented complexity. An innovative algorithm based on a volumetric analysis defines the layout of the internal cuts in the silicone mold part. Our approach can robustly handle thin protruding features and intertwined topologies that have caused previous methods to fail. We compare our results with state of the art techniques, and we demonstrate the casting of shapes with extremely complex geometry.

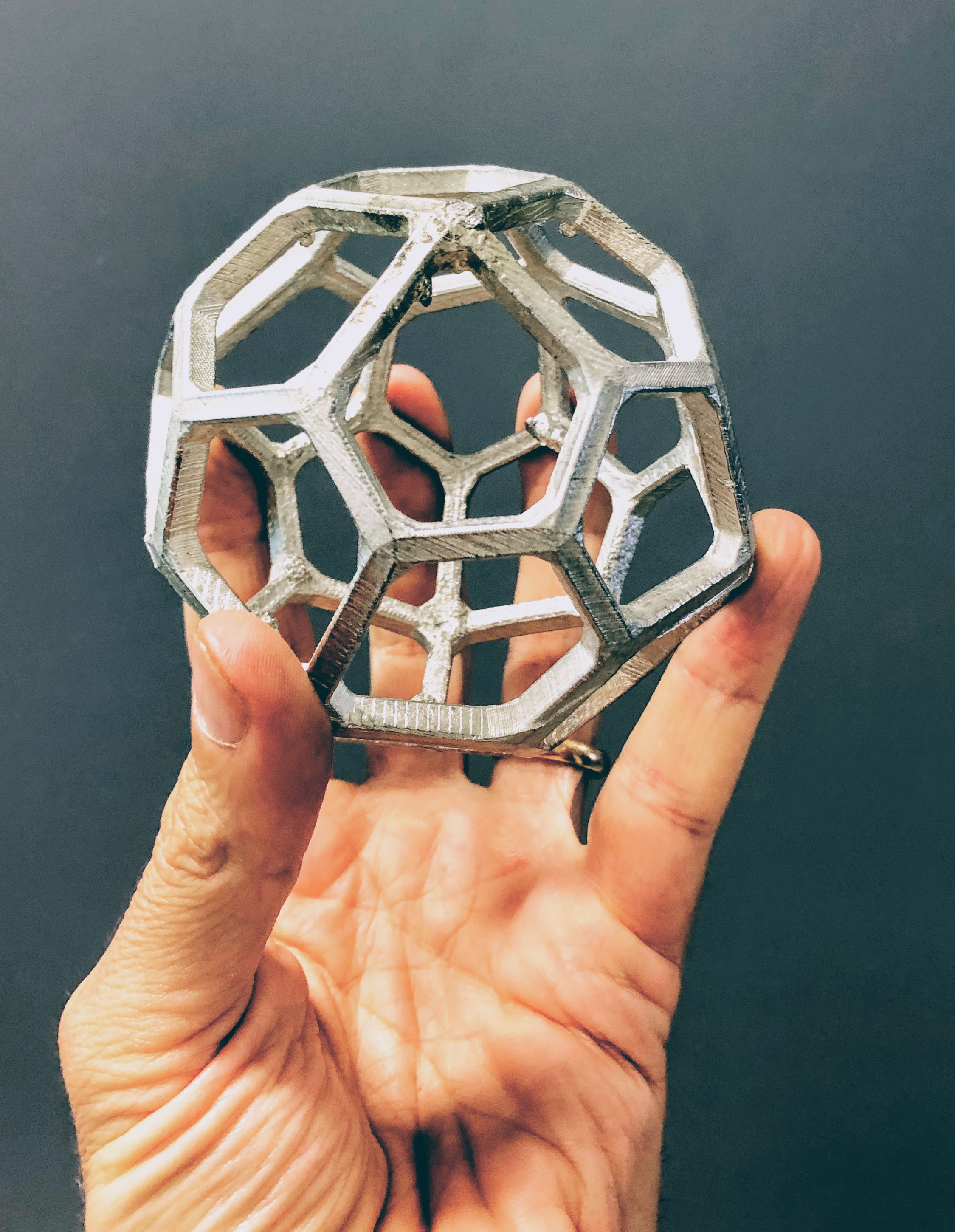

Acknowledgment Errata Corrige: we forgot to list in the acknowledgment the source of one of the model the caged knot, namely the one used in the above teaser. The Catalan Solid cage containing the knot is a derivative work of the Pentagonal Icositetrahedron by Laura Taalman>.